HOT printing

Cosmelux elevates packaging to an art with hot stamping: an exclusive technology that combines luxury and precision. Brilliant metallic effects, pearlescent and opaque finishes, transferred with heat and pressure onto materials such as plastic, glass, metal and more, create unique and valuable surfaces, both simple and complex. Professionalism and craftsmanship, combined with strict quality control, make hot stamping the ideal choice for exclusive packaging. Because luxury is form and substance.

the BENEFITS

- Media versatility | Hot stamping ensures brilliant, high-strength metallic effects on plastic, glass, metal and other surfaces, including flat, round, elliptical and complex surfaces.

- Integrated technology | Thanks to a process combining hot stamping and pad printing, it is possible to decorate even raw or painted glass with precision, adapting to delicate and precious materials.

- High quality and craftsmanship | professional staff and strict quality controls ensure excellent results, combining handcrafted details and industrial procedures.

- Luxury customised effects | Metallic, pearlescent, matt or glossy foils are transferred using advanced techniques, making the packaging exclusive and refined.

Production capacity

Production capacity for standard size parts: 60,000 pcs total

Machinery

4 Semiautom. flat printing

2 Automatic round printing

Company Certifications

DIN ISO 9001:2015

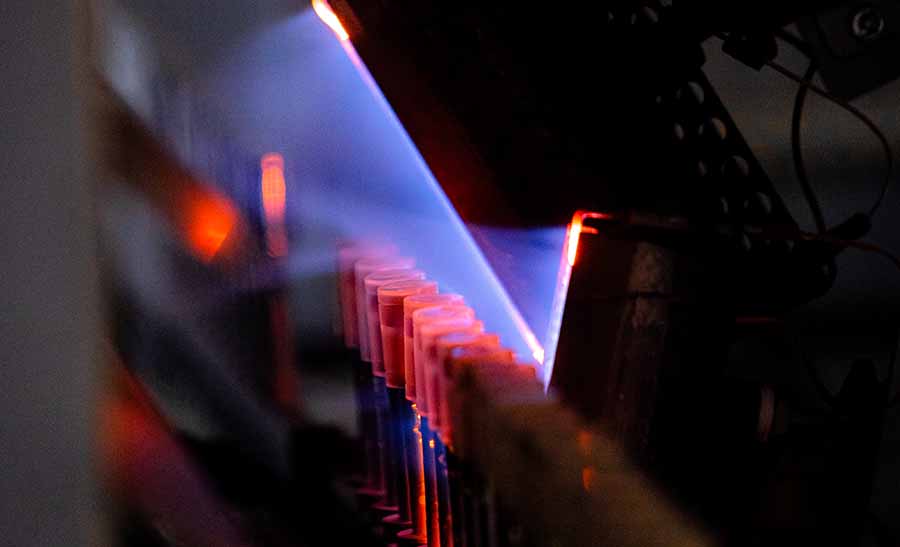

pvd | Thermal evaporation plants

In the field of decorative metallisation, the adoption of thermal evaporation systems is still the most widespread system today due to its simplicity of use and its deposition efficiency in the presence of substrates with very complicated geometries.

The deposition source consists of tungsten resistors, generally placed in the centre of the process chamber, on which the wire of the metal to be deposited is placed.

Substrates are positioned around the resistors and are rotated (rotation and translation) during the metal deposition phase.

In order to achieve metal deposition within the process chamber, it is necessary to reach a vacuum level generally higher than 4×10-4 mbar (high vacuum).

Once the necessary vacuum level is reached, the actual evaporation phase begins, which consists of heating the tungsten heating elements, which are made incandescent and melt the metal, which evaporates and condenses on the surface of the substrate.

pvd | Sputtering

A modern, fast and inexpensive metal deposition system originally used only on substrates with flat surfaces, it is now increasingly used on three-dimensional objects as well, even with simple geometries.

In sputtering technology, the deposition source is a magnetic cathode on which a metal plate (target) of the desired material is placed.

The magnetic cathode is generally placed at the side of the process chamber. The substrates rotate in front of the deposition source. When the desired vacuum level is reached, a high voltage is applied and Argon is injected.

The positive Argon ions undergo an acceleration process on the negative cathode and subsequently eject the atoms from the metal plate. These atoms then condense on the substrates.

- Address Via Del Dosso 1 | 20841 Carate Brianza (MB)

- Phone +39 0362 8000 88

- Email info@cosmelux.it

Disclosure requirements for public disbursements: State aid and de minimis aid received by our company are contained in the National State Aid Register under Art. 52 of Law 234/2012′ and can be consulted at the following link by entering the tax code of your company as a search key in the field FISCAL CODE.

Copyright 2025 Cosmelux. All rights reserved.